ABS Modified Resin Engineering Plastic Granule Compound PC ABS for Automotive Interiors

Overview Package size per unit product 50.00cm * 70.00cm * 100.00cm Gross weight per unit product 25.000kg Product Descr

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | ZG-751 |

| Color | White |

| Application | Car Accessories, Breaker, Connector |

| Sample | Available |

| Delivery Time | 3days |

| Process | Injection Molding |

| Tensile Strength | 7250 Psi |

| Flexural Strength | 11310 Psi |

| Customized | Yes |

| Transport Package | Environmental Protection Woven Bag |

| Specification | 25kg/Bag |

| Trademark | FLXSH |

| Origin | China |

| HS Code | 3907991090 |

| Production Capacity | 20000tons/Year |

Packaging & Delivery

Package size per unit product 50.00cm * 70.00cm * 100.00cm Gross weight per unit product 25.000kgProduct Description

What is PC-ABS?Polycarbonate (PC-ABS) is an engineering thermoplastic made from a mixture of PC and ABS. The unique performance balance depends on the ratio of PC to ABS in the mixture, the molecular weight of the polycarbonate, and any thermoplastic additives in the mixture. The ratio of PC to ABS will significantly affect the heat resistance of the final component.Why choose PC-ABS?Engineers and product teams turn to PC-ABS when their use cases require the toughness and heat resistance offered by PCS and the malleability and machinability offered by ABS. PC-ABS is also a more cost-effective alternative to PCS.Material properties and specifications of PC-ABSPC-ABS plastics are one of the most widely used engineering thermoplastics in the world due to their mechanical properties. The material has high strength, high stiffness, high heat resistance and high impact resistance even at low temperatures. PC-ABS maintains its dimensional stability over time, and its enhanced flow characteristics and machining properties make it easy to use. Because PC-ABS is colourable and printable, designers have a great deal of latitude when using the material.technical specification

| Item | PC+ABS | Model | |||||

| Product characteristics | Shading | Method of processing : Injection molding | |||||

| Test Environment:Constant temperature and humidity | |||||||

NO. | Proofing Courses | Test Conditions | Test Standards | Units | Test Results | ||

| 1 | Melt Index | 220ºC,10kg | ASTM D-1238 | g/10min | 17.8 | ||

| 2 | Density | / | ASTM D-792 | g/cm3 | 1.14 | ||

| 3 | Mold Shrinkage | 150×100×3.2mm | ASTM D-955 | % | 0.4-0.7 | ||

| 4 | Tensile Strength | 50mm/min | ASTM-D-638 | Mpa | 50 | ||

| 5 | Breaking Elongation | 50mm/min | ASTM-D-638 | % | 33 | ||

| 6 | Flexural Strength | 2mm/min | ASTM-D-790 | Mpa | 78 | ||

| 7 | Flexural Modulus | 2mm/min | ASTM-D-790 | Mpa | 2537 | ||

| 8 | IZOD Impact strengthnotched | 23ºC,3.2mm | ASTM-D-256 | J/M | 78 | ||

| 9 | HDT | @1.82MPA | ASTM-648 | ºC | 93 | ||

Application

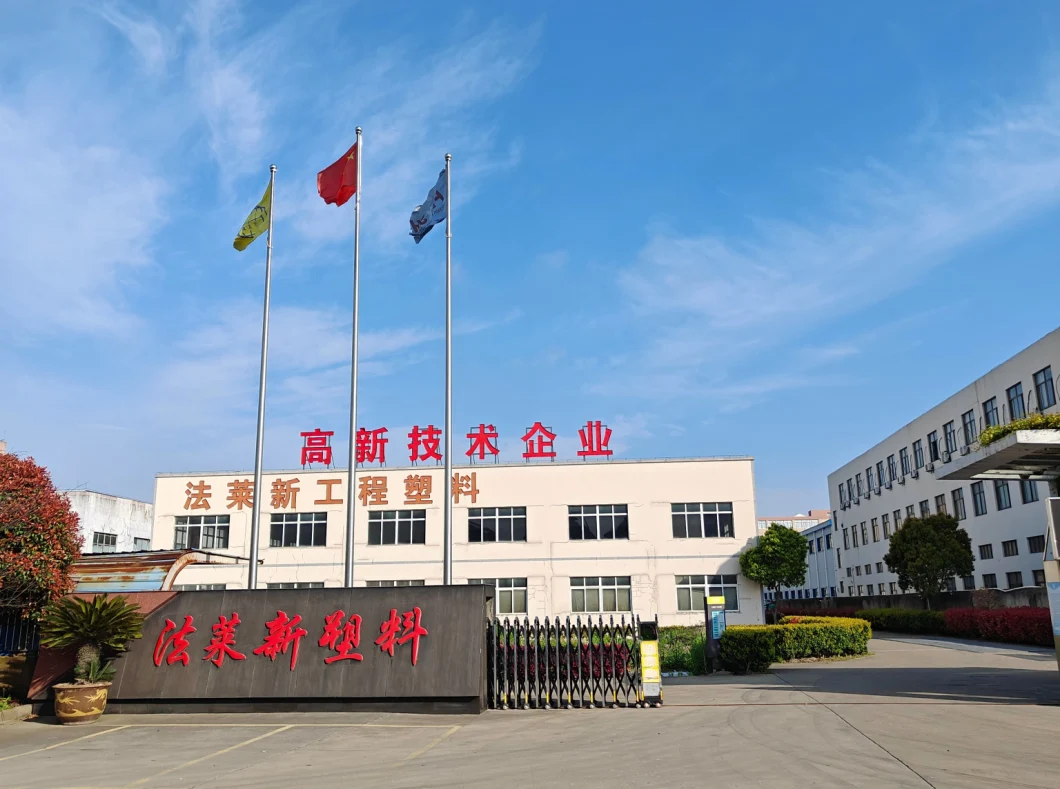

Company Profile

We are a factory specializing in modified plastics in China, which has a history of more than 30 years in China.The factory covers an area of more than 10,000 square meters. The main production equipment includes 10 sets of twin screw extruder, 2 sets of single screw extruder, 5 sets of injection molding machine, 6 sets of blender and 10 sets of granulating machine.The main scope of PC alloy series (halogen-free flame retardant PC/ABS, PC/PBT, PC/PET), modified PC series (halogen free flame retardant, the main products | enhanced, cold resistant, anti-aging, anti-static, wear resistance, should crack resistance, etc.), modified ABS (flame retardant, high temperature resistance, high impact, highlights, etc.), New materials (PC light diffusion material, PC reflective material, PC shading material, etc. We are the factory side, you can be assured to choose us, with the highest attitude to every transaction.

Production line

Laboratory

CONTACT:Ms Linda

COMPANY:Ningbo Seiling FALAIXIN New Material Co., LTD

ADDRESS:No. 68, Pengyuan Road, Binhai Economic and Technological Development Zone, Cixi City, Ningbo, China

A: Yes, we can supply free sample, you pay for the freight charge only.Q2: How to pay?

A: PI will be sent firstly after our aligned products specification. Payment by Paypal , T/T, Western Union,LC, are ok.

Q3:What's your delivery time?

A: Generally 7-15 days after payment for small quantity. For large quantity, the delivery time will be informed after confirm.Q4:Can I get a cheaper price if I order a large quantity?

A:If you order a large quantity, the discount would be possible based on the quantity you require.Q5: How can you guarantee the quality of your products ?1. Our staff are all experienced in Plastic Raw Material and chemical products who have related major background.2. We can assure the same specification as sample before you place commercial order.3. Third Party can inspect according to your requirement before shipping.Q6: Do you have any other plastic raw material or chemicals?

A: Yes, We can provide kinds of such as PP, PE,PVC,PET,ABS,PC,Color Masterbatch,and Detergent Raw Materials,Adhesive,etc...Any questions, contact us!

Related Products

-

![IP66 Waterproof Outdoor Line Light Fixture for Landscape Lighting]()

IP66 Waterproof Outdoor Line Light Fixture for Landscape Lighting

-

![OEM Custom CNC Industrial Lighting Heatsink Anodizing Heat Sink Profile Powder Coating Extruded Aluminum]()

OEM Custom CNC Industrial Lighting Heatsink Anodizing Heat Sink Profile Powder Coating Extruded Aluminum

-

![Modified PC/ABS Impact 45 Black Flame Retardant High Impact High Flow]()

Modified PC/ABS Impact 45 Black Flame Retardant High Impact High Flow

-

![6063 Aluminum/Aluminium Alloy Plate /Sheet Casted/Extruded/Rolled]()

6063 Aluminum/Aluminium Alloy Plate /Sheet Casted/Extruded/Rolled